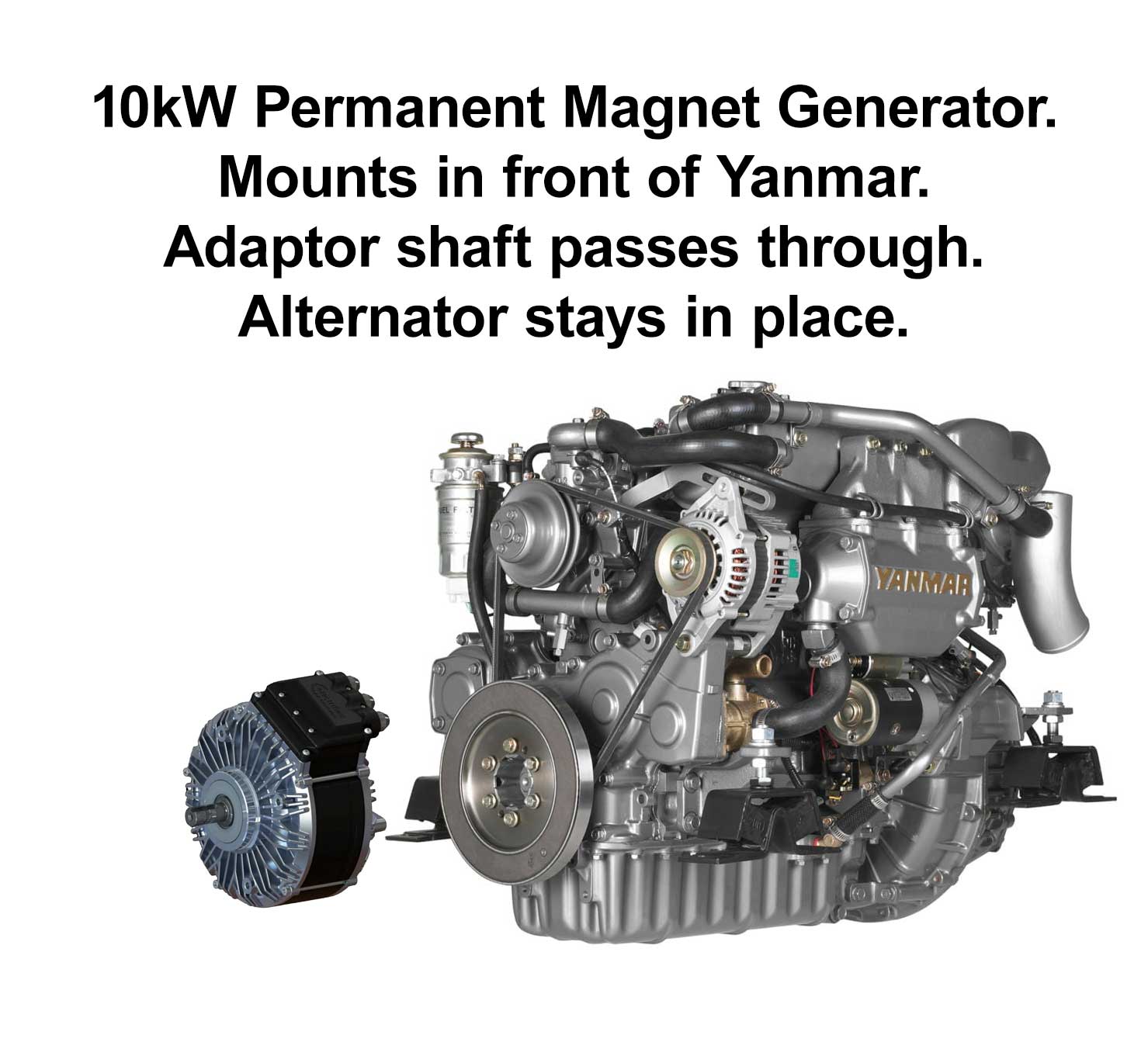

Scotty AI BMG +Controller + 48-12V DC DC + Yanmar Mount

AUD9,850.00

1 × Permanent Magnet Generator High Efficiency 10kW with Yanmar Mount

Available on backorder

Available on backorder

We are focussing on the side or pad mount BMG which offeres greater flexibility at same output power for Marine market. We will re-introduce this unit at 20kW Power in Q3 2025

Comparison of Permanent Magnet Generator and traditional Alternator

-

- 1. Efficiency:

- Permanent Magnet Generator (PMG): PMGs are known for their high efficiency, often exceeding 90%. This efficiency is due to their design, which minimizes energy losses during power generation.

- 48V Alternator: Traditional alternators typically have lower efficiency, ranging between 55% and 75%. This is primarily because of energy losses in the conversion process and mechanical components.

2. Maintenance:

- PMG: With fewer moving parts and the absence of brushes or slip rings, PMGs require minimal maintenance, leading to longer service intervals and reduced downtime.

- Alternator: Alternators have components like brushes and slip rings that are subject to wear and tear, necessitating regular maintenance to ensure optimal performance.

3. Power Output and Stability:

- PMG: Designed to provide consistent power output with minimal fluctuations, PMGs are suitable for applications requiring stable voltage and current, which is crucial for charging lithium batteries.

- Alternator: Alternators may experience voltage fluctuations, especially under varying load conditions, which can be less ideal for sensitive charging applications.

- 1. Efficiency:

4. Size and Weight:

- PMG: Generally more compact and lighter due to their efficient design, PMGs are advantageous in applications where space and weight are constraints.

- Alternator: Alternators can be bulkier and heavier, potentially posing challenges in installations with limited space.

5. Compatibility with Lithium Batteries:

- PMG: The stable and efficient power output of PMGs makes them well-suited for charging lithium batteries, which require precise charging parameters to ensure longevity and safety.

- Alternator: While alternators can charge lithium batteries, they may require additional regulation to maintain the appropriate charging profile, adding complexity to the system.