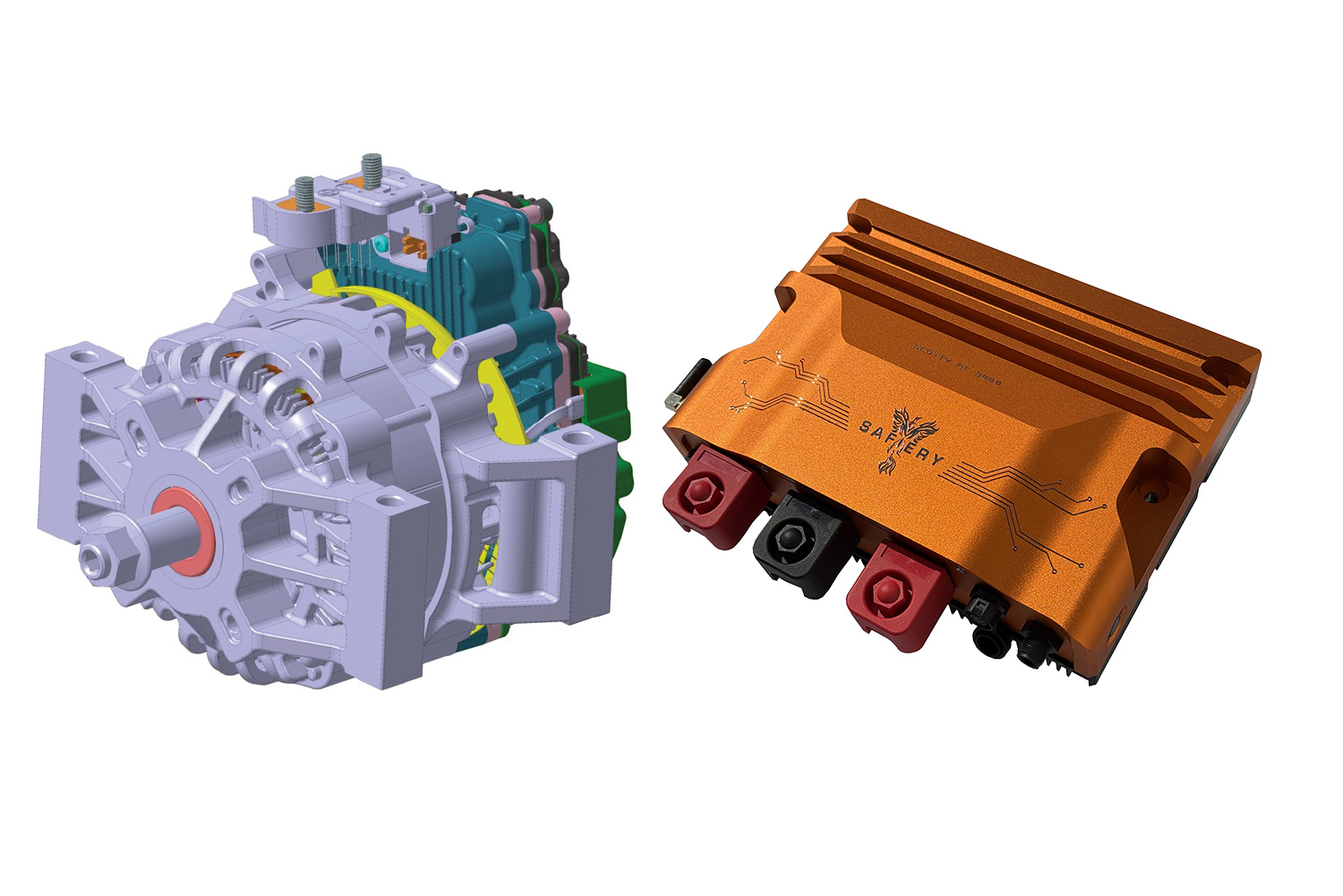

48V BiDirectional Motor Generator Volvo Mount with 12V 3000W Auxilliary Power

AUD8,970.00

48V BiDirectional Motor Generator Pad Mount with 12V 3000W Auxilliary Power

AUD8,970.00

BMG-4804 - J-180 Large Marine Mount Suits Volvo and Cummins

AUD5,665.00

BMG-4803 - J180 Mount

AUD5,665.00