Current forms of utility grade power generation, such as gas turbines are only 20-35% efficient. It is also important to note that 60% of energy used for electricity generation is lost in the process. In short, the current way of delivering electrical power to your home is grossly inefficient.

Solar is 20-25% efficient and MPPT power conversion is 98% efficient. If these two are at your home, its an improvement in overall efficiency.

- Keeping power at the DC level is the most efficient.

- Converting DC power to 240V AC is around 95% efficient.

- Charging AC to DC is very inefficient with 20% losses.

In mobile applications, low efficiency losses manifest as heat. Many things don’t like heat and at the top of the list is power electronics. For example a typical 240V AC battery charger is around 80% efficient. As it heats up it becomes even less efficient and derates in performance. Most of the industry DC DC converters operate in the 80-85% range. Some switch to half power after 30 minutes or so when they get incredibly hot.

One reason Lithium batteries are so popular is because of efficiency. They are 99% efficient. Whereas any of the lead/acid technologies including AGM and Gel batteries are 75-80% efficient. You have to put 125W of solar into an AGM battery to get 100W out.

Scotty is 96% efficient in either direction. So combined with Solar MPPT controllers at 98% efficient and Lithium at 99% efficient, the round-trip efficiency is high.

Safiery will be producing battery operated Bluetooth switching systems in 2023. To operate the switches on battery power for over a year requires high efficiency at 99.5%+. The benefit is reduced wiring costs and increased functionality with up to 6 switches activating the same device. There is no negative impact on reliability. Without super high efficiency, this is not achievable.

Scotty and Alternator on Engine Efficiency is Higher than you think

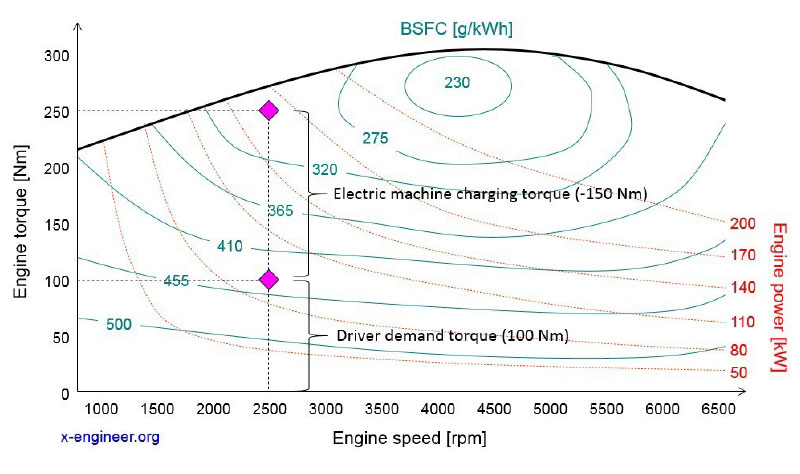

A way of improving efficiency with diesel engines, is where engine excess torque can be used to generate electrical energy and charge the battery. Minimizing the brake specific fuel consumption is by shifting the engine load into a more efficient area while maintaining the same engine speed.

In the example above, the vehicle is moving at a constant speed. The vehicle speed translates in a point of engine torque (100 Nm) and speed (2500 rpm). The engine efficiency in this operating point, 455 g/kWh, is far from optimal. By increasing the engine torque to 250 Nm we decrease the brake specific fuel consumption to 320 g/kWh. The excess torque (150 Nm) will be compensated by the electric machine (-150 Nm) which will run in generator mode and produce electrical energy.