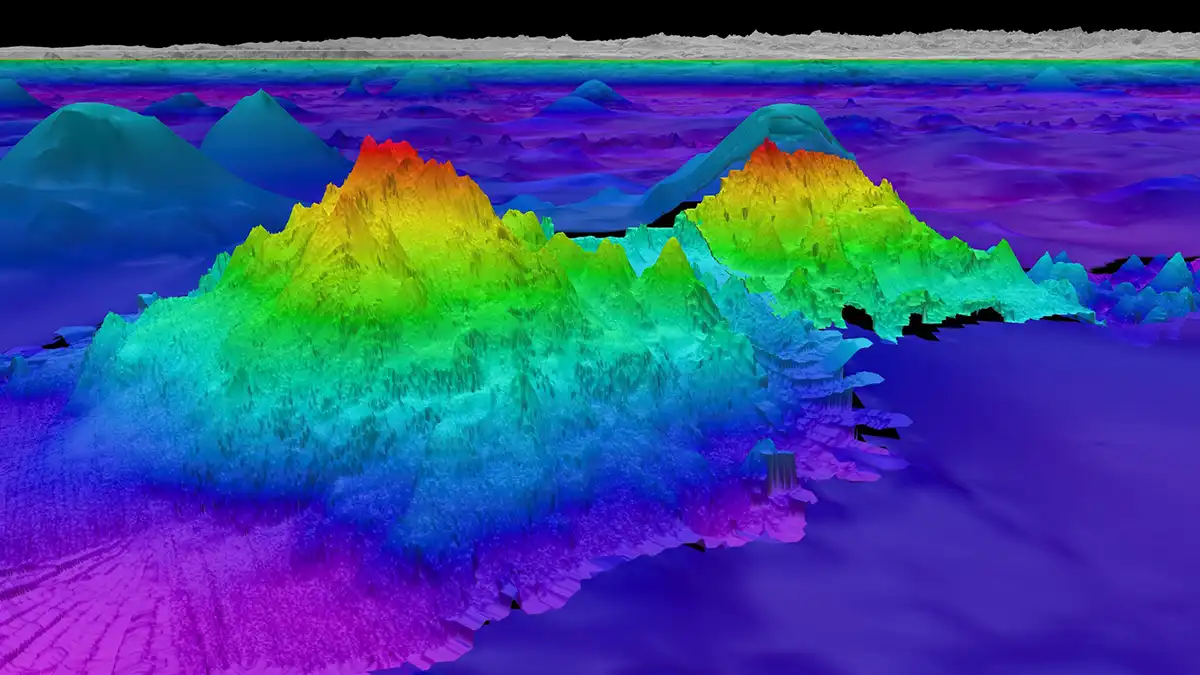

An underwater mapping vessel in California refitted by Woopert Marine needed a new electrical system. The owner wanted professional digital switching integrated fully with the Victron Energy power system. But they didn’t want the high cost or complex installation that usually comes with it.

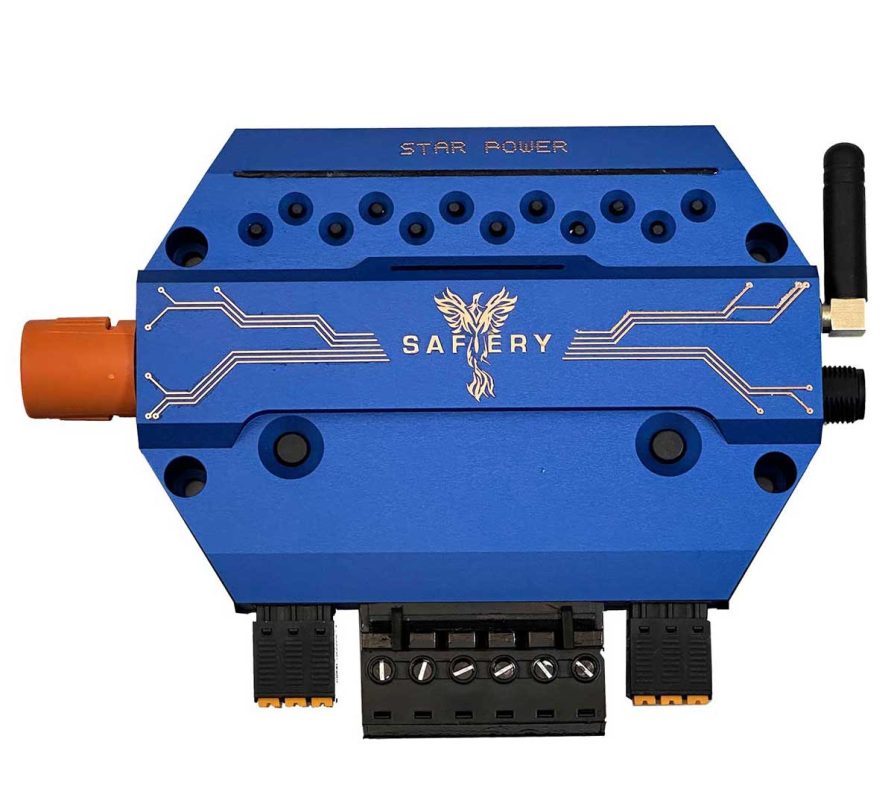

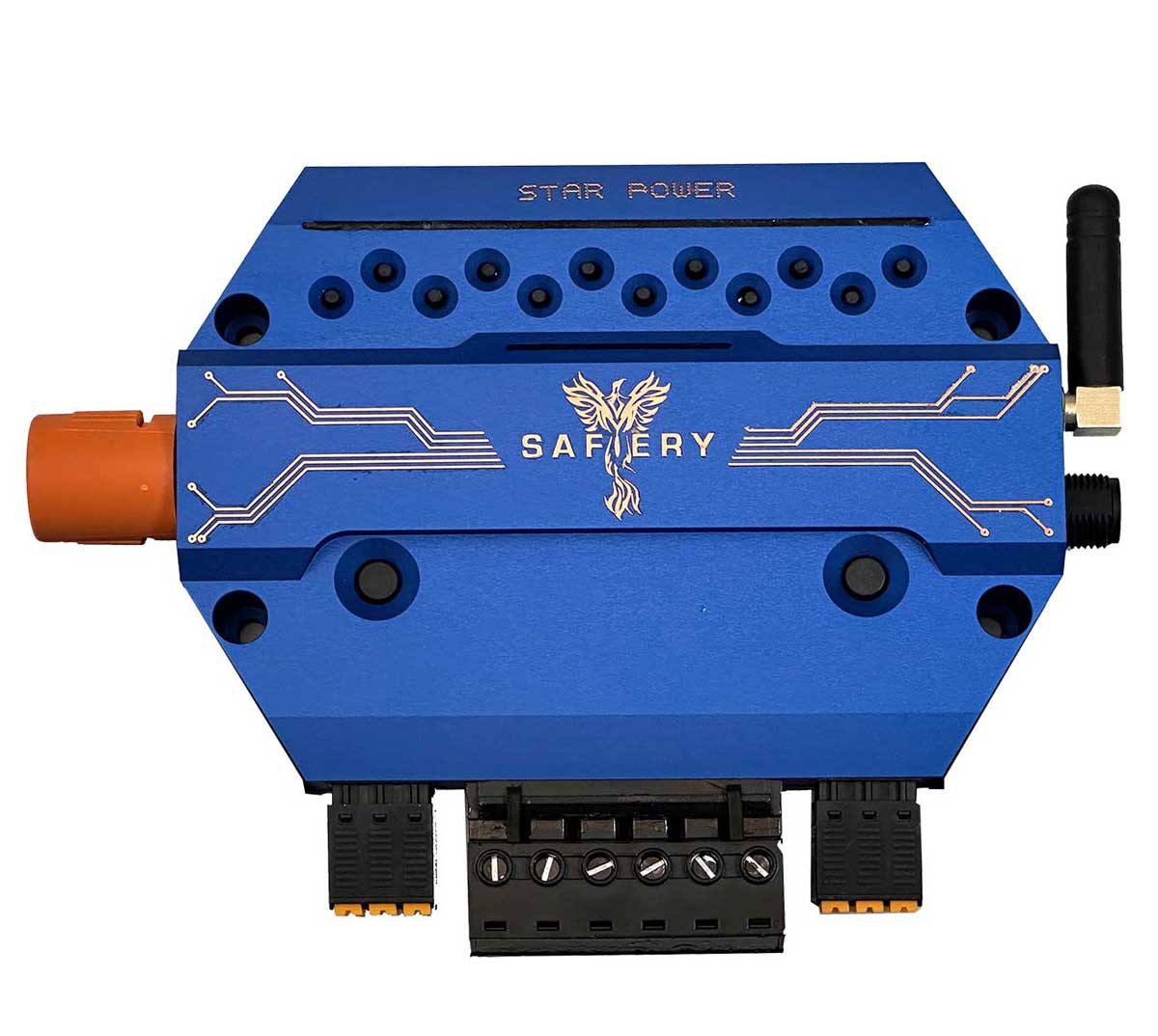

The answer? Two STAR-Power units and one STAR-Light controller. The system exceeded expectations. And it cost less than half the original budget.

The Challenge

Underwater mapping vessels work in tough conditions. They need reliable electronics. The vessel required:

- Strong switching for high-power loads

- Multiple pumps and navigation equipment

- Precise lighting control

- Clean, professional appearance at the helm

- Fast installation to reduce downtime

Old-style marine switching would need many fuse panels. It would need complex wiring. It would take a lot of installation time.

The STAR Solution

No Fuses = Faster Installation

STAR Controllers have advanced fuseless protection built in. No fuse panels to mount. No fuse holders to wire. No spare fuses to carry.

The result? Much faster installation. Cleaner wiring. A more organized electrical system.

Perfect Power for Every Load

The two STAR-Power units gave them exactly what they needed:

- 10A channels for lights and smaller loads

- 30A channels for all the bigger equipment

Every load got the right size channel. No oversized wiring. No external relays needed.

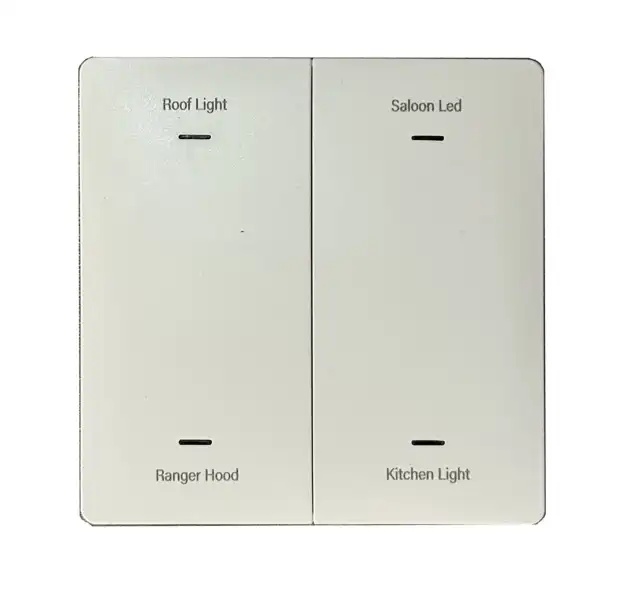

Wireless Switches Save Major Time

Four sets of wireless switches went in the back of the boat. Each set has 4 buttons for lighting control.

The old way: Run control wires from the helm to the back. Go through walls. Add waterproof connections. Hours of work. High material costs.

The STAR way: Mount wireless switches where you need them. Done.

The time savings was huge.

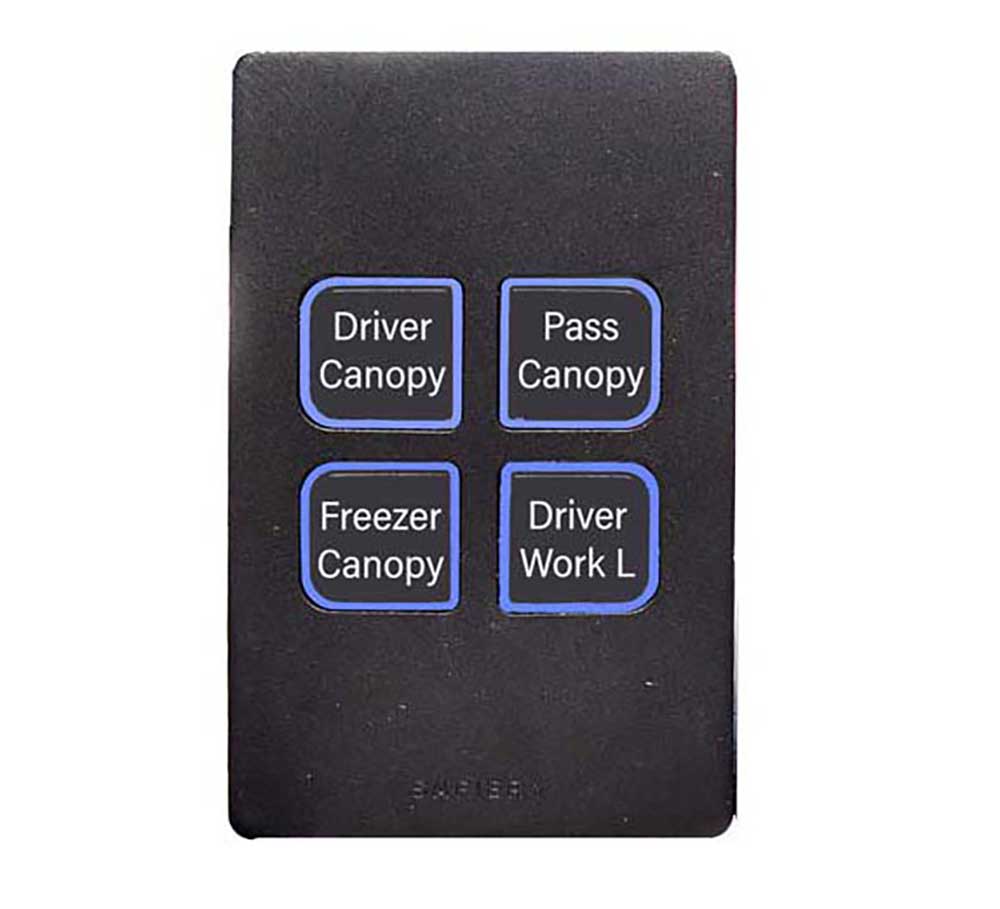

Custom Helm Switches Look Factory-Perfect

The helm uses STAR’s CAN switches with custom engraved buttons. The result looks like it came from the boat factory.

No generic labels. No temporary solutions. Just clean, professional switches.

The complete digital switching system cost less than half the planned budget.

What they got:

- ✅ Professional digital switching

- ✅ No-fuse protection

- ✅ Wireless control

- ✅ Factory-quality look

- ✅ Faster installation

- ✅ Easy maintenance

- ✅ Money left for other upgrades

The owner said it best: “Big savings for big smiles.”

Why This Installation Matters

This California install shows what makes STAR Controllers different:

Faster to Install – No fuses and wireless options cut installation time way down.

Right-Sized Channels – Mix 10A and 30A channels to fit every load perfectly.

Professional Look – Custom switches and clean design rival factory installations.

Better Price – Professional features without the premium cost.

Proven Reliable – Working great in a demanding commercial vessel.

What Was Installed

- 2x STAR-Power – 16 channels total (10A and 30A options)

- 1x STAR-Light – Extra lighting control

- 4 sets of wireless switches – Back deck control (4 buttons each)

- Custom engraved CAN switches – Helm control

Professional Marine Made Easy

This installation proves something important. You can get professional digital switching without compromise. You don’t have to choose between performance and budget.

The underwater mapping vessel now has an electrical system that’s simple to use. It’s easy to maintain. It was fast to install. That’s exactly what professional marine work needs.

Want STAR digital switching for your vessel?

Contact Safiery to learn how STAR Controllers can make your next installation easier and more affordable.

STAR Controllers – Smart Marine Electronics

-

STAR Digital Switching System

STAR-Power Wireless 6 x 35A + 6 x 10A Channel Switching 12V or 24V Integrates with Victron

AUD924.00 Add to cart -

STAR Digital Switching System

STAR-Light Wireless 12 Channel 10A for 12V or 24V Device Integrates with Victron

AUD892.50 Add to cart -

STAR Digital Switching System

STAR-Switch Icon Interchangeable CAN Keypad 8 Button IP65

AUD446.00 Add to cart -

STAR Digital Switching System

STAR-Rover-4 Wireless and CAN 4 Channel 15A for 12V or 24V Device Integrates with Victron

AUD409.50 Add to cart -

STAR Digital Switching System

STAR-Switch Custom 6 wired Inputs Logic Integrates Victron

AUD249.00 Add to cart -

STAR Digital Switching System

STAR-switch SP4 Wireless Battery 4 Button Switch

AUD206.85 Add to cart -