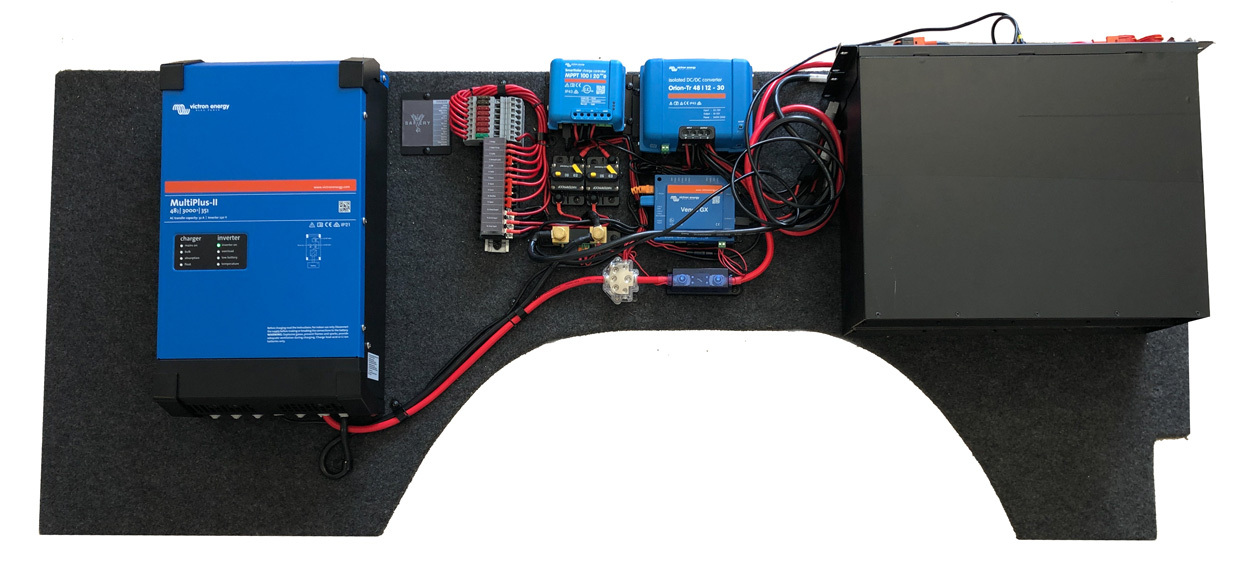

Regulation Compliant inside Van 2000W Inverter 200Ah Sodium Batteries 50A DC DC

AUD5,990.00

- up to 6 battery banks,

- 6 additional battery voltages

- 14 tank levels (for temperature monitoring)

- 20 consumer or power generation readings.

Note: The price added to the cart is exclusive of GST.

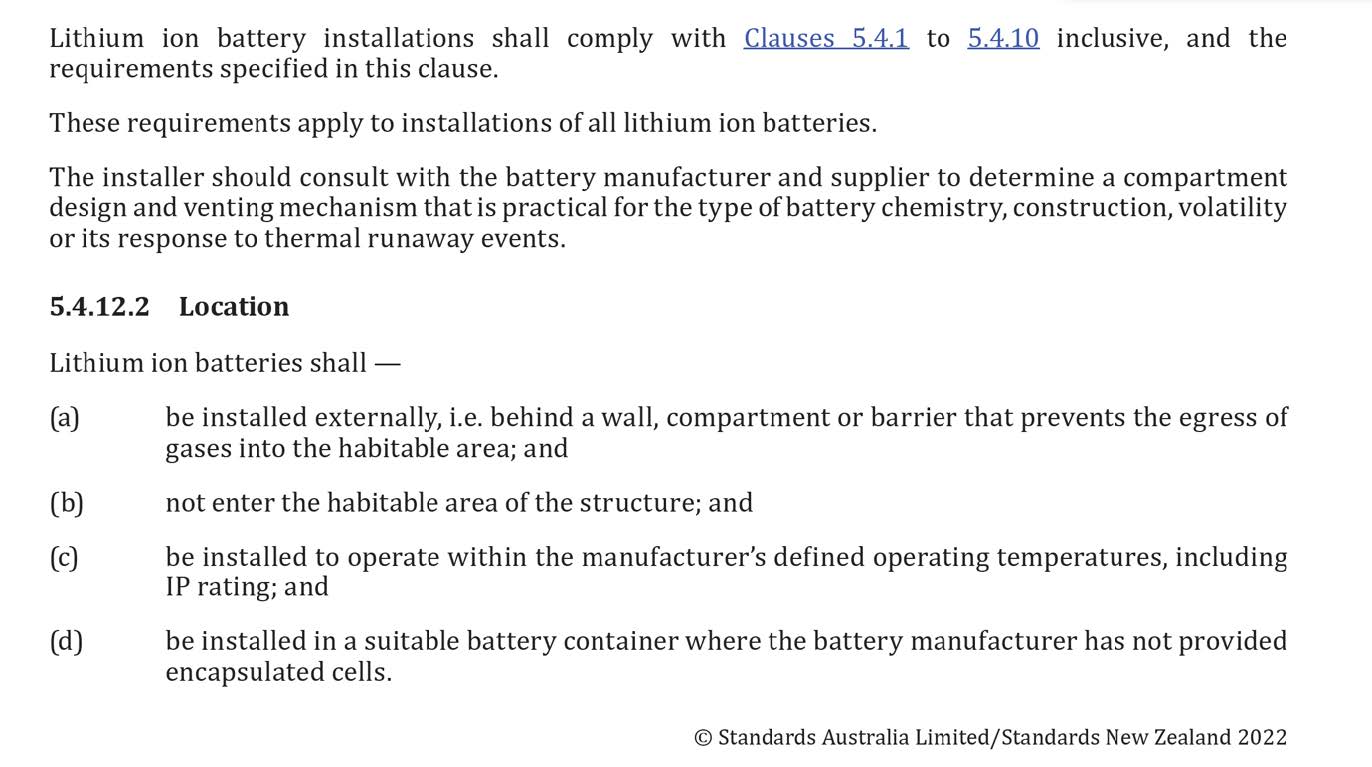

Regulations on Lithium Ion (includes Lithium Iron Phosphate and all other Lithium based chemistries) prohibit installing these batteries inside a van without external access.

The reasons are very simple: In the event of a fire, access is needed to the lithium storage area without entering the van.

If these rules aren't followed to the letter, insurer's may not oblige.

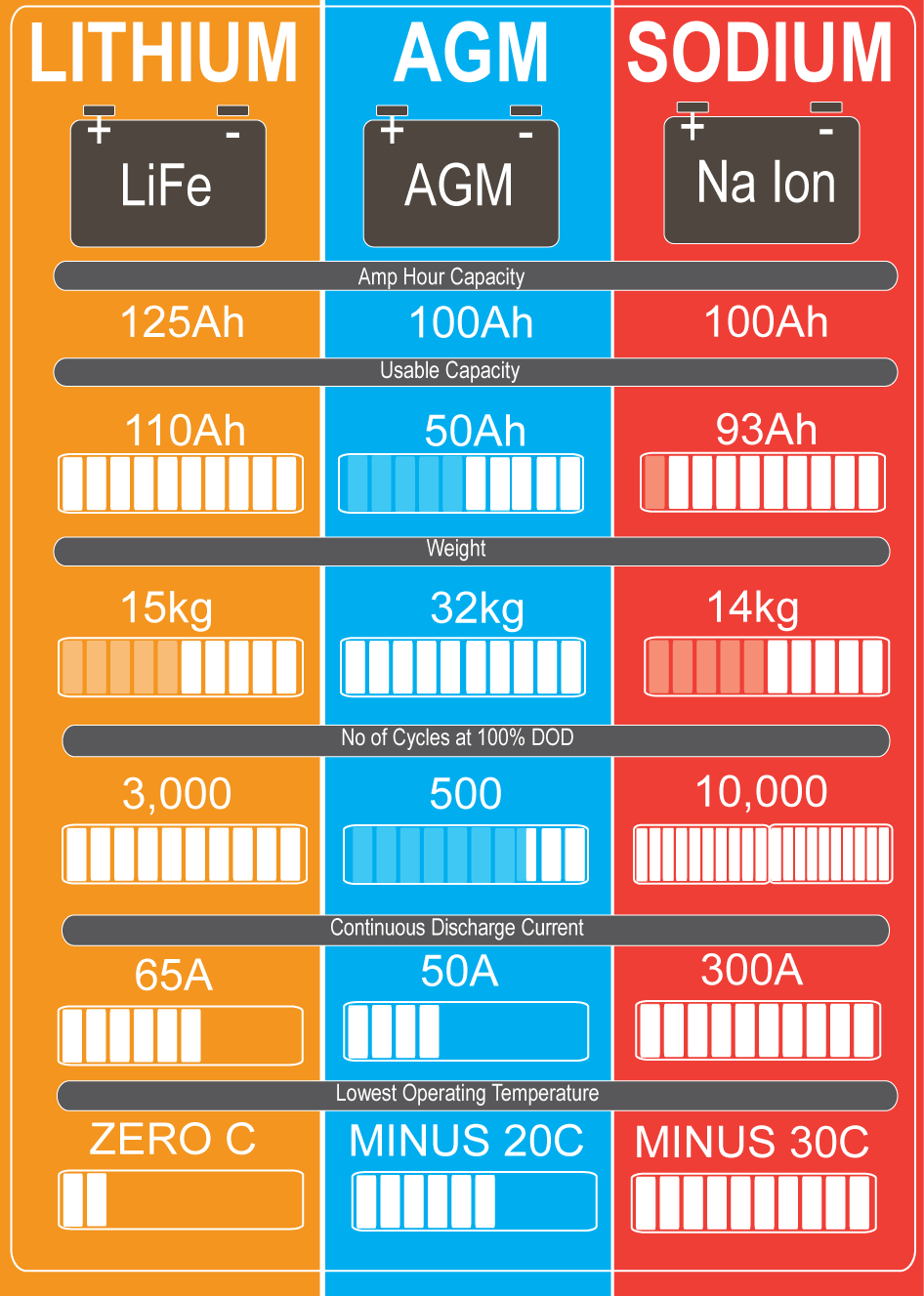

Sodium Batteries are not included in this rule. They dont have the same danger of thermal runaway that lithium batteries have.

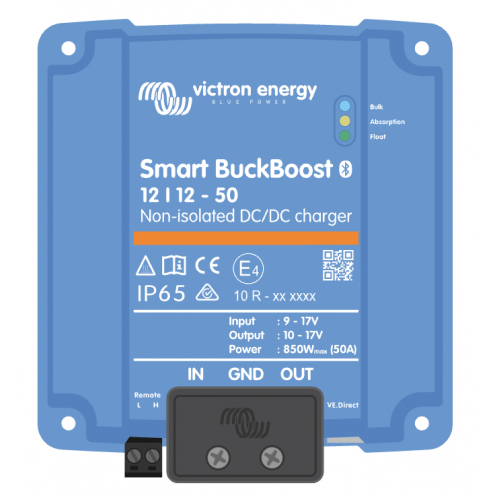

New Victron 50A DC DC packs a punch

This DC DC charges at 50A continuously. It is one of the new breed os ultra-high efficiency DC DC's which are so compact.

There are no heat fins behind this Orion XS model. They simply aren't needed. There is so little heat. This makes placing inside a van so much more sensible.

Victron increased the range of this DC DC especially for Sodium Batteries. Sodium batteries need to charge up to 15.8V. They also drop lower in voltage to around 8V. But thanks to Victron technology we are able to deliver a constant 12.8V for the fridge, lights and water pump.

The Victron 3000VA Inverter charger is also 100% compatible with Sodium batteries. Sodium Ion is now popular in Europe because of the low operating teperature of -20C for charging, even lower for discharging.

The Victron Smart Solar Controller is also 100% Sodium Compliant with charging and MPPT control.

Its not the Battery Capacity that is Crucial...

Its the size of the recharge capacity.

The correct way to size a power system is to ensure the recharge capacity is greater than your enery usage.

The battery size is then a buffer for overnight and days without driving.

- A typical fridge uses 1,000Wh a day.

Induction cooking for two people with use a similar amount. - The LED lights, water pump and fans use very little, say 300Wh a day.

- Charging phones about 300Wh a day.

So a typical van setup uses around 3000Wh a day as a minimum. This means:

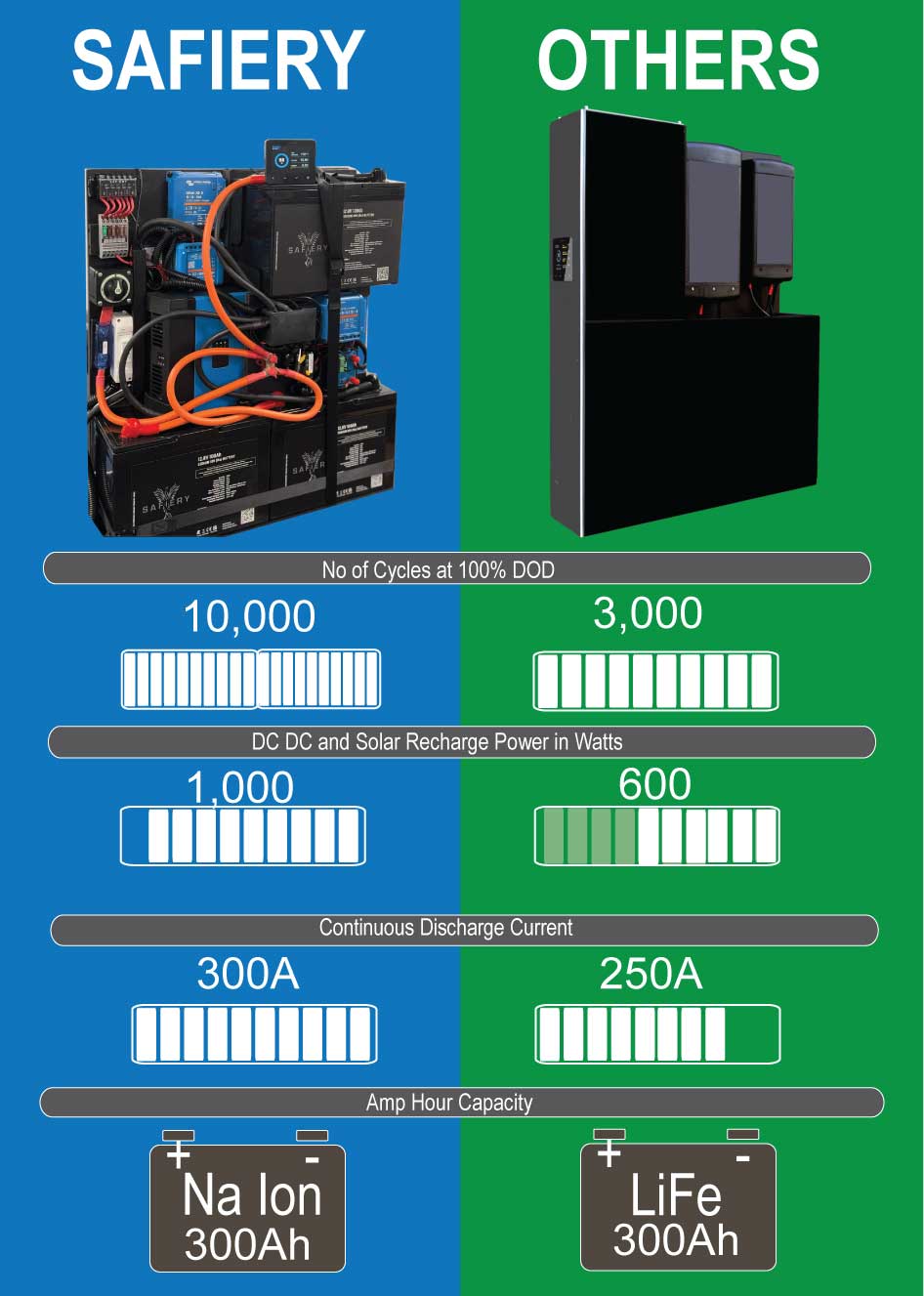

- 1000W Recharge will need 3 hours of driving with very poor solar or 2 hours with great solar.

- 600W Recharge will need 5 hours of driving or 4hours + with solar.

Now you see the incredible difference a high recharge rate makes to your energy needs.

300Ah of Sodium on the Board

Has a discharge rate of 300A at 12V

Has a Charge Rate up to 300A. In this case the AC charger will charge at 80A. The DC DC Charger at 50A and the Solar Controller at 20A even when the DC DC charger is running.

The Batteries Weigh 14kg each.

The Entire Board with the Inverter and Batteries Weighs 75kg.

The Board Dimensions are:

650mm Long, 620mm high and 200mm deep.

It is designed to slide into a cupboard but can be laid flat.

The Top battery can be re-positioned to the floor.

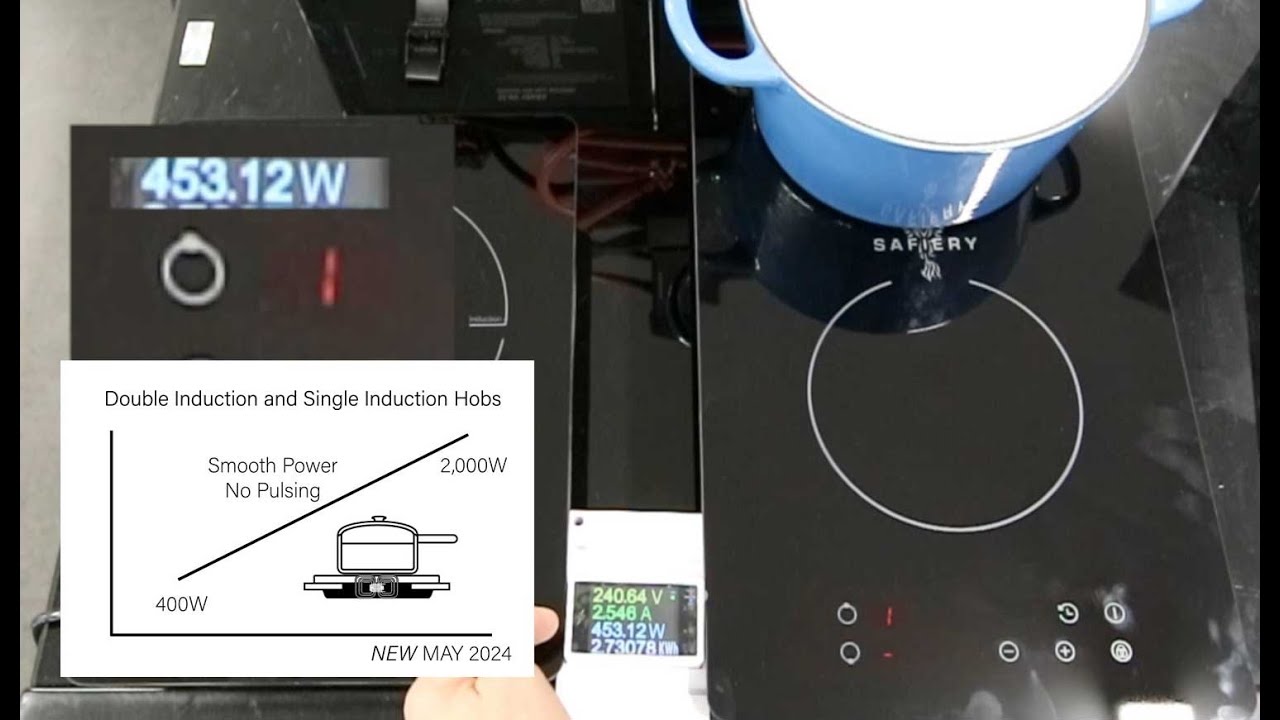

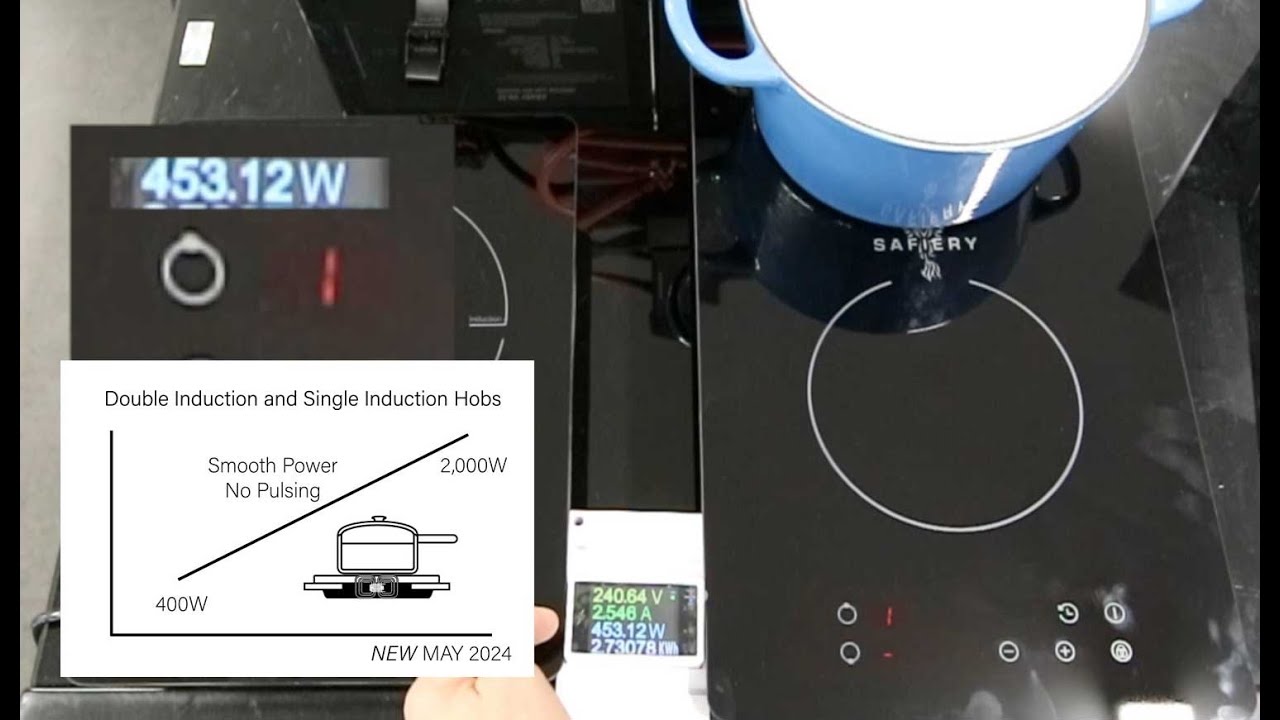

No Pulsing Control with Safiery Inductions

Double Induction Smooth Power

Using double induction with smooth power rather than pulsing power at low power levels offers several significant benefits:

1. Enhanced Control:

The continuous and stable power supply enables better control over the cooking. This precise control allows for accurate adjustments to the power level, ensuring optimal performance and desired outcomes in various applications.

2. Improved Efficiency:

Smooth power delivery in double induction systems ensures a more efficient utilization of energy. By avoiding sudden spikes and drops in power, the system can operate more consistently, leading to better energy efficiency and reduced wastage.

3. Reduced Eddy Current Losses:

Eddy currents are minimized with smooth power delivery, as there are no abrupt changes in magnetic fields that can lead to losses. This reduction in eddy current losses contributes to higher overall efficiency in the system.

4. Minimized Heating Issues:

Pulsing power can sometimes lead to localized heating in the system, which may affect components and reduce their lifespan. With smooth power delivery, the risk of overheating is reduced, promoting longevity and reliability of the equipment.

5. Consistent Heating:

In processes that require precise and uniform heating, such as in induction cooking or industrial applications, smooth power delivery ensures consistent heating throughout the material. This results in better quality outcomes and improved process control.

6. Noise Reduction:

Pulsing power can generate electromagnetic interference and audible noise in induction systems. By utilizing smooth power delivery, noise levels can be reduced, creating a quieter working environment and minimizing disruptions.

7. Extended Equipment Lifespan: The stable power supply provided by double induction with smooth power helps in prolonging the lifespan of induction equipment. Reduced stress on components and consistent operation contribute to increased durability and reduced maintenance requirements.

In conclusion, opting for double induction with smooth power at low power levels offers a range of benefits including improved efficiency, enhanced control, reduced losses, minimized heating issues, consistent heating, noise reduction, and extended equipment lifespan. These advantages make this approach a favorable choice for applications where precision, reliability, and energy efficiency are paramount.

lorem ipsum

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

lorem ipsum

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

lorem ipsum

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.