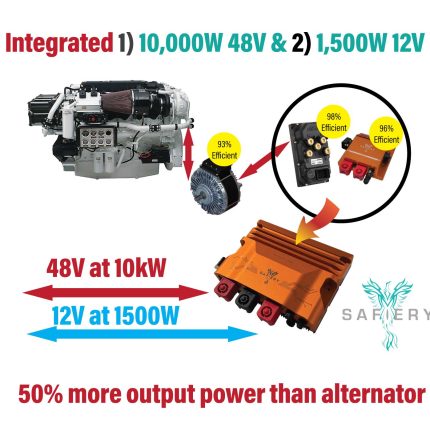

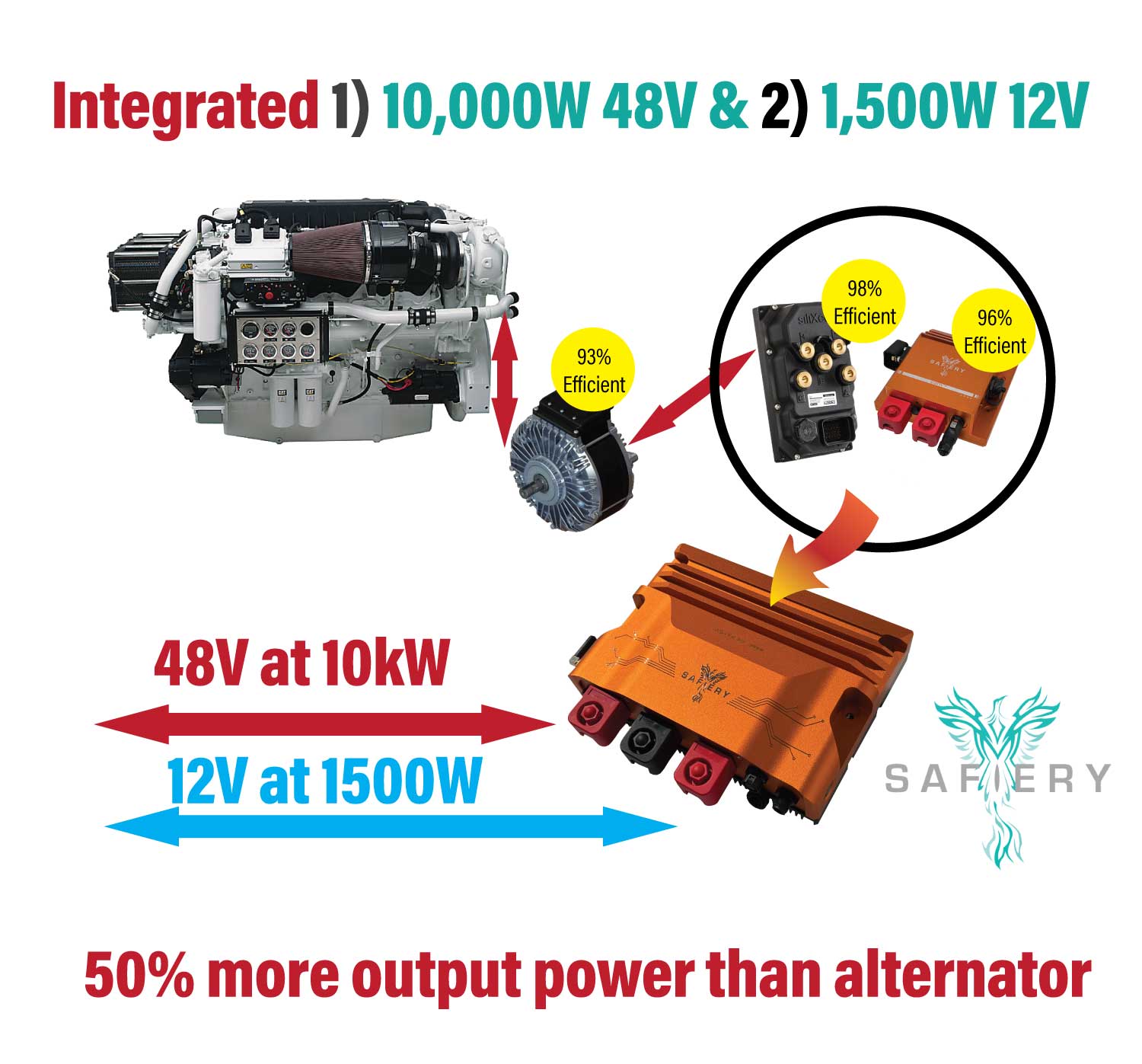

High Efficiency Generator plus DC DC

This package has three parts:

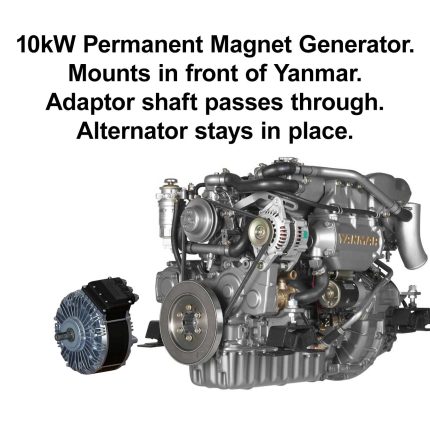

- 10kW high Efficiency Permanent Magnet Generator at over 92% efficiency.

Sets this at 10kW engine load for 9.3kW electrical output. Compare to an alternator at 60% efficiency: 10kW engine load produces 6kW electrical output.

PMG produces 50% more output for same engine load. - Silicon Carbide Inverter/Charge to control the PMG at 98% efficiency. It has supervisory control from Scotty AI connected by CAN to lithium battery bank.

- 48-12V DC DC at 1500W with Scotty AI Patented control system. No 12 battery is required. up to 125A at 12V can be produced.

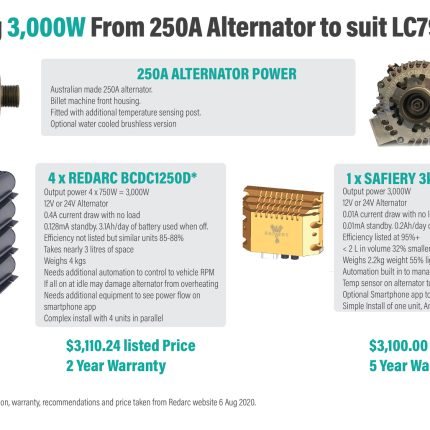

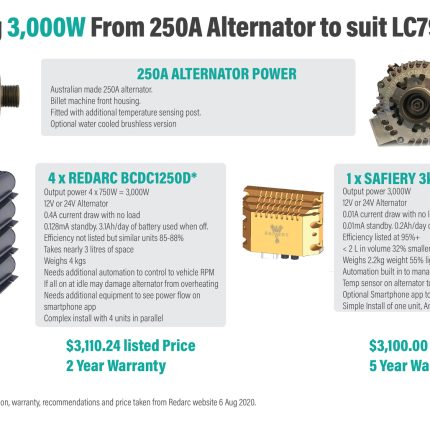

Comparison of Permanent Magnet Generator and traditional Alternator

1. Efficiency:

Permanent Magnet Generator (PMG): PMGs are known for their high efficiency, often exceeding 90%. This efficiency is due to their design, which minimizes energy losses during power generation.

48V Alternator: Traditional alternators typically have lower efficiency, ranging between 55% and 75%. This is primarily because of energy losses in the conversion process and mechanical components.

2. Maintenance:

PMG: With fewer moving parts and the absence of brushes or slip rings, PMGs require minimal maintenance, leading to longer service intervals and reduced downtime.

Alternator: Alternators have components like brushes and slip rings that are subject to wear and tear, necessitating regular maintenance to ensure optimal performance.

3. Power Output and Stability:

PMG: Designed to provide consistent power output with minimal fluctuations, PMGs are suitable for applications requiring stable voltage and current, which is crucial for charging lithium batteries.

Alternator: Alternators may experience voltage fluctuations, especially under varying load conditions, which can be less ideal for sensitive charging applications.

- PMG: Generally more compact and lighter due to their efficient design, PMGs are advantageous in applications where space and weight are constraints.

- Alternator: Alternators can be bulkier and heavier, potentially posing challenges in installations with limited space.

- PMG: The stable and efficient power output of PMGs makes them well-suited for charging lithium batteries, which require precise charging parameters to ensure longevity and safety.

- Alternator: While alternators can charge lithium batteries, they may require additional regulation to maintain the appropriate charging profile, adding complexity to the system.

- Higher Efficiency: The SCOTTY AI V3 PMG is an Interior Permanent Magnet (IPM) motor/generator, known for superior efficiency compared to traditional alternators. This results in 50% more effective energy conversion during regenerative processes than using an old style alternator.

- Compact and Lightweight Design: Weighing approximately 18 kg and measuring 208 mm in diameter with a length of 172.8 mm, the SCOTTY AI V3 PMG is designed for high power density. This compactness facilitates easier integration into various systems, especially where space and weight are critical factors.

- Higher Power Output: While a traditional alternator may be limited to 6 kW, the SCOTTY AI V3 PMG can deliver a peak power of up to 32 kW and a rated power of 10 kW, providing greater capacity for energy regeneration.

- Durability and Environmental Resistance: The SCOTTY AI V3 PMG is fully certified to IP69K standards, ensuring it can withstand high-pressure and high-temperature washdowns. This makes it suitable for harsh operating marine environments where traditional alternators might be susceptible to damage.

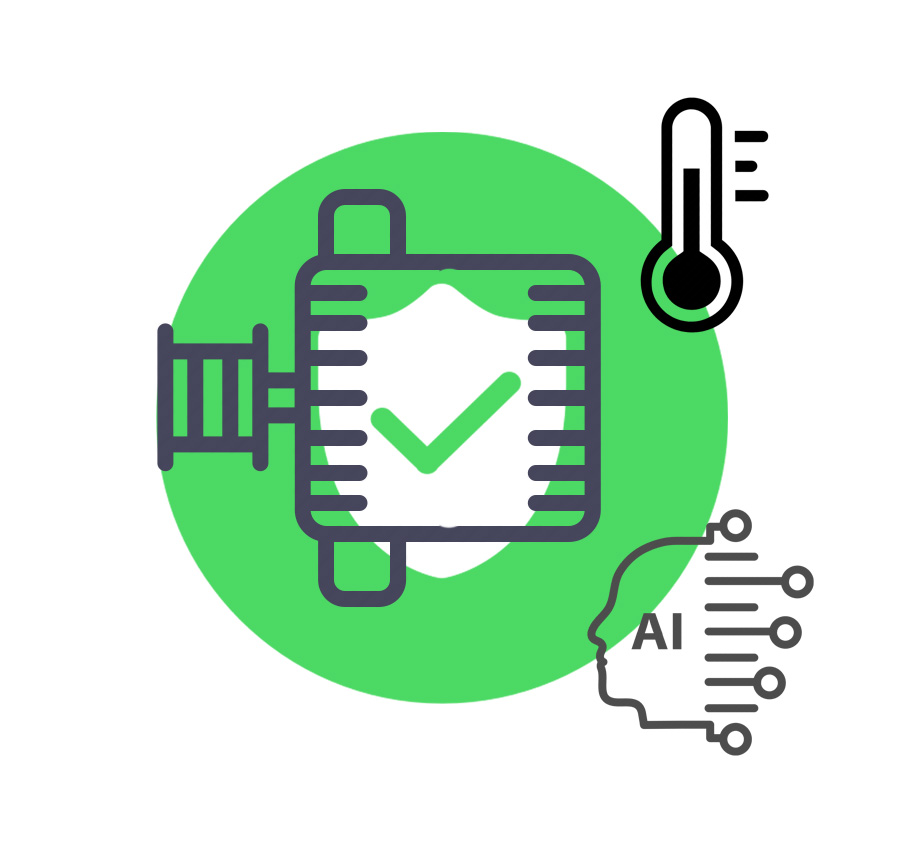

- High power density: Advanced technology and an emphasis on efficient heat dissipation from the most stressed areas allow us to maintain the control unit's dimensions as small as possible.

- Modularity: Individual blocks of the control unit are designed as modules that are shared among various controller models and variants. This provides users with a high degree of flexibility, and transitions between models do not pose complications.

- High dynamics: An extremely fast control loop for phase currents ensures precise current control and very rapid response to changes in control signals.

- Advanced protective features: Thanks to precise control of phase current and temperature control at critical points, the controller is robustly protected against overcurrent and overheating.

- VCU (Vehicle Control Unit): Integration of a high-performance microprocessor allows the implementation of vehicle engine assessment functions directly into the controller, thus maximizing PMG output without overloading the engine.