Showing all 10 results

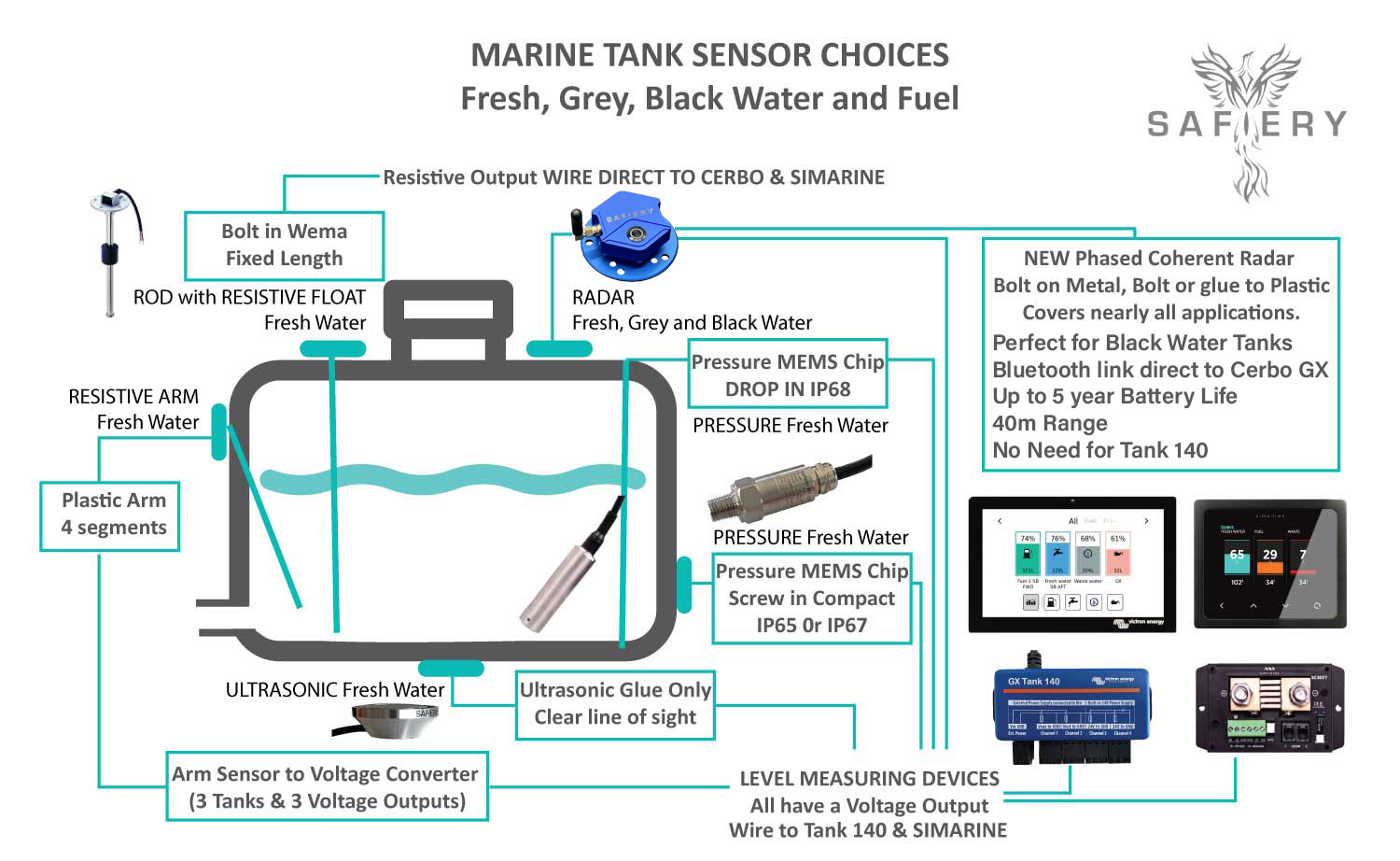

Different Technology for WATER, GREY WATER and FUEL TANKS

Resistance Slider | Pressure Level | Ultrasonic | Radar |

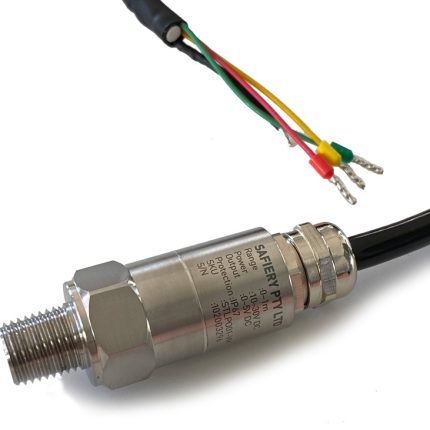

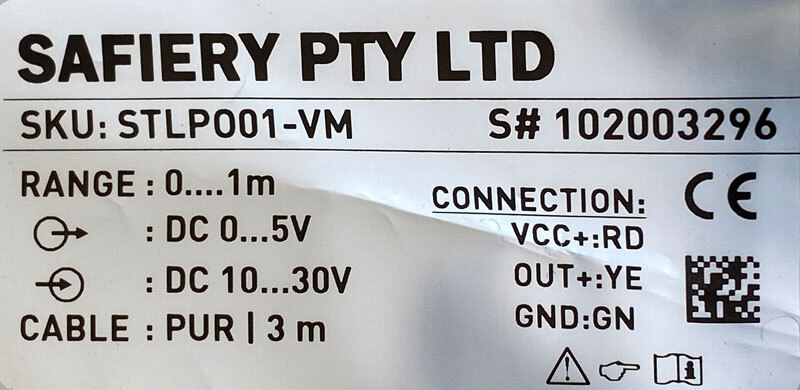

Passive measurement of resistance as a magnetic ring slides up and down a hollow shaft with resistors embedded internally. | Active measurement of pressure in a tank using a silicon wafer that “bends” under pressure and creates a signal. Resultant signal may be voltage, NMEA, CAN or or Bluetooth data. | Active measurement of distance from under a tank (or above tank for Some) to the air-water interface point. Resultant signal may be voltage, NMEA, CAN or or Bluetooth data. | Active measurement of distance from top of tank to air-liquid interface point. Resultant signal may be voltage, NMEA, CAN or or Bluetooth data. |

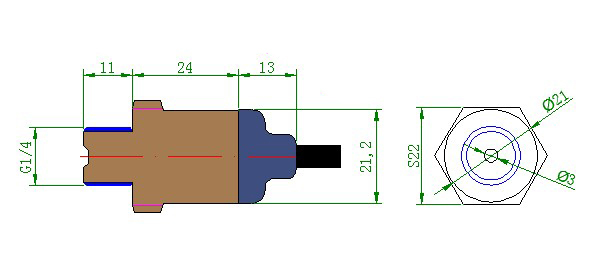

Above Tank with height access to remove the unit of similar height of tank. | Side of tank as close to bottom as possible. Needs a threaded boss on tank to screw into. | Below tank must use a couplant of grease or glue. Cant have intermediate layer. | Above tank for non-metal tanks can sit directly on top of tank (glue) and for metal tanks, needs hole with SAE 5 bolt pattern. |

20-30mm Accuracy | Varies with quality but typically 20mm | Varies with quality but generally average | High accuracy of 1mm is achievable. |

No active power. Just 2 wire to resistance sensor. | 3 wire of power and voltage value and ground. | 3 wire of power and voltage value and ground or battery Bluetooth. | Battery operate Bluetooth or CAN/NMEA powered 12/24V. |

N/A | N/a | 3-5 years battery life | 5 years Battery Life Enhanced by AI |

Stainless steel components | Stainless steel components | Plastic and embedded sensor | Billet machined Aluminium and embedded liquid proof radar sensor. |

Not Suitable for Black water and troublesome in grey water measurement | Not Suitable for Black water and troublesome in grey water measurement | Not Suitable for Black water and troublesome in grey water measurement | Perfect for black water, grey water even with foam on top. |

Comparison of Ultrasonic and radar tank Sensors to STAR-Tank

| Mopeka | Gobus C | STAR-Tank | |

| Technology | Sonar (ultrasonic) | Radar | Radar |

| Placement | Below tank Flat 12mm | Above tank 65mm required | Above tank 30mm required |

| Accuracy | Affected by foam and temperature | High | High |

| Power | Battery | 12/24V | Battery |

| Calculated Battery Life | 3-5 years | N/A | 5 years Enhanced by AI |

| Warranty | 1 year | Not Listed | 5 years excluding battery for above non-metallic tanks. 1 year for application in metal tank with SAE 5 bolt hole. |

| Victron Integration | Bluetooth ADV | Resistance | Bluetooth ADV |

| Price Point in Euros | Euro 65 | Euro 350 | Euro 165 |

| Available Now | Available Now | Available Now | Available September 2024 |

Disadvantage of Ultrasonic or Sonar Sensors

Non invasive tank level sensors have been limited to Ultrasonic up til now. Ultrasonic sensors operate at around 100kHz. If under the tank, the signal may be blocked by solids or material in the water. If above the tank, they are susceptible to foam and general interference from reflection. They are just not suitable for Black Water or Grey Water. and suffer from reflective errors. They have limited accuracy.

Radar technology is now Affordable

Phased Coherent radar operates at 60GHz and penetrates foam with great accuracy. Up until now, Radar has been an expensive choice and used in very high value applications. But the introduction of Phased Coherent Radar to EV's opened the door for inexpensive tank sensor applications.

In pulsed coherent radar, a series of short-duration radio frequency pulses are transmitted towards the water line from above. These pulses are reflected back and received by the radar system's antenna. The received signals are then processed and analyzed to determine the depth.

The term "coherent" refers to the radar system's ability to maintain a constant phase relationship between the transmitted and received signals. This coherence allows for more accurate measurements and improved signal processing techniques, such as coherent integration, which enhances the radar's sensitivity and range resolution.

Pulsed coherent radar systems are commonly used in various applications, including military surveillance, air traffic control, weather monitoring, and automotive radar systems. They offer advantages such as high accuracy, long-range capabilities, and the ability to distinguish multiple targets in close proximity.

Video Showing Phased Coherent Radar raw signal

and corresponding tank level

as sensor is moved above water.

This is the most advanced software development we have developed as there are 3 independent IC's. fresh libraries had to be created.